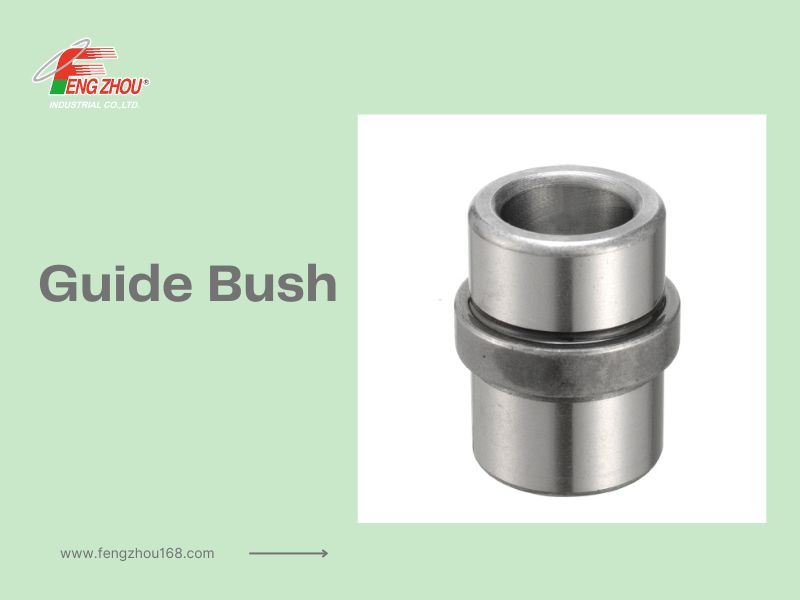

In this article, we will compare several common materials used in the manufacture of guide bushings, helping you decide which one best suits your needs.

In injection molding, a guide bushing is a key part. It guides the mold halves or components inside the mold, ensuring they move correctly.

In the complex field of precision engineering, one small part plays a crucial role in machine efficiency: the guide bushing. This component is essential for ensuring machines work smoothly and last longer across various applications.

In the demanding world of manufacturing, choosing the right materials for machine components like guide bushings is crucial. This article explores the characteristics and benefits of SUJ2 steel, a material known for its durability and resistance to wear, and how it compares to other materials such as copper. Specializing in SUJ2 steel guide bushings, Fengzhou Precision Mold Limited exemplifies the integration of material excellence into product performance, ensuring that each bushing meets the rigorous demands of modern industry.

Guide bushings ensure the precise alignment and smooth operation of guide pins within a mold. By reducing friction and wear, they extend the life of both the mold and the guide pins, which is crucial for maintaining production quality and efficiency.

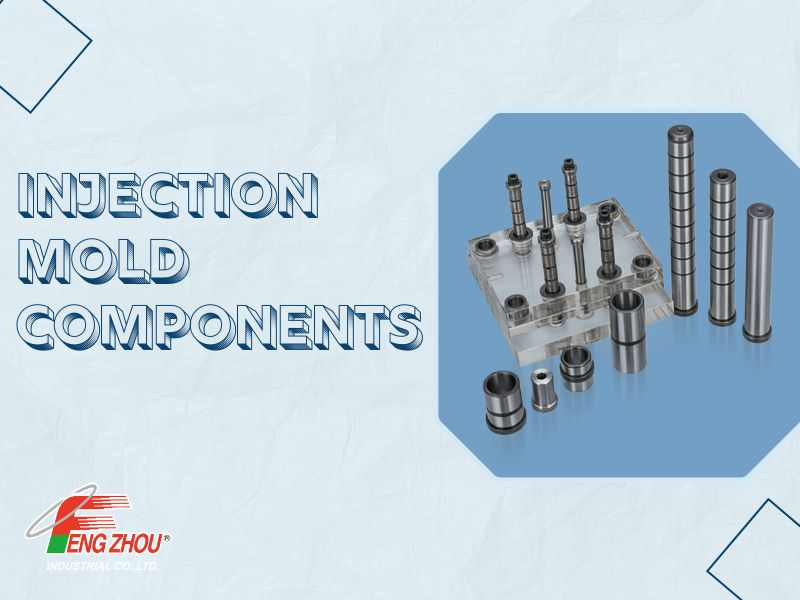

In the sophisticated world of plastic injection molding, the quality of every part hinges on the precision and reliability of its mold components. FengZhou stands at the forefront of this technology, crafting essential components that ensure the efficiency of production and the excellence of the final product. From guide pins that ensure flawless alignment to support pillars that provide unwavering stability, join us as we delve into these components and their indispensable roles in injection molding.

LASTEST TECHNOLOGY